Last Friday January 7th we had our first snow storm of the year, it dumped 30 cm, this past Friday January 14 we got another one which brought us 41 cm of snow.

Better not be another one this next Friday...

Last time I was not well prepared, should had my snow blower serviced. This time I remembered it on Wed morning called them to pick it up and they delivered it back Thursday PM. in time for this one.

Checked it out in my driveway, pushed back the snow banks, checked out Jean on starting/operations, got gas, storm beers, chips and dog treats. Ready Aye Ready

Good thing cause this one was a whooper.

You know it was windy when you find snow at the door.

Also mean door wont open until I clear snow in front.

The old one piece swinging door

Looking out the garage door window.

Hum yeah, need to clear some snow

Garage door makes a poor shovel, have to clear it.

And we are off to snow banks.

Bring it on!

21 inch high bucket plus snow banks cutter, about 26 inch high

and still snowbanks towering above. No sweat :-)

The front entrance

Typical of the paths I cleared around the property

for the greenhouse, sheds and dogs trails :-)

About the height of the bucket a good 21 inch everywhere

With big gusty winds up to 90 kmh, we got higher drifts.

Very happy with that snow blower, its a big snow beast.

Ariens Deluxe Made in USA, thick strong steel, heavy duty transmission, twin belts driven arg arg arg. It will do :-)

Compared to my older one (Yard Works, green) I lost 2 inches on the bucket width (28 versus 30 in) and some in height . Engine is a bit smaller 12.5 HP versus 13HP for the old one, but it is more aggressive due to its auger shape. Electric start, a concession for Jean but it start easy and smoothly on the first pull.

Meanwhile...

I was impressed by Ralph results cleaning his plane's depth brass adjuster with ZEP citrus cleaner, so I got some and gave it a try.

The specimen I picked, untouched, as received.

It is from a Union No 4 plane

Dump some in a cup to completely submerged it.

I keep a loose fitting lid just to prevent mess and slow down evaporation

This is the crud left from my brass adjuster

After a few hours soaking, blotted and quick look

Some scrubbing with a brass brush and put back in to soak

Left overnite, taken out, dried with a towel and given a quick hand brushing all over.

Pretty easy and impressive results. Recommended.

Sparkling clean effortlessly, it's a keeper

Would shine to a high buff.

Shown besides new shiny brass on my miter gauge.

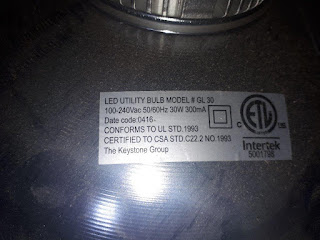

Lately two of my newer LED light fixtures failed. Not too impressive, one not quite one year old the other maybe 2 or 3 years, start to flash intermittently then went out.

They were both about Cdn $50 each, not cheap :-(

I liked them, lots of lights, bought 3 of the folding arms variety, 2 in the storage room and one providing main illumination in the middle of my shop.

The light fixtures in question.

The Tri-wing came from storage side, the one with big reflector

was over my built in bench in the shop

Date code Nov 2020, not even a year in service.

That one has a date code of Apr 2016 but was purchased later

and installed a few years later.

About 3 years service?

Lets have a look at the Tri-wing first.

That one just quitted suddenly.

Double sided circuit boards.

No physical damages apparent, no loose components.

A few questionable solder connections perhaps, reworked.

I could not read the part numbers on the ICs, the flash revealed them.

It has a 5 Amp fuse at the input, it does test short :-)

After reassembly and testing I noticed the difficulty of tightening solidly the lamp into the socket.

Something seems to be turning loose and wont tighten.

Oh yes, see one of the wire turning into a pigtail?

The one on the side does not move when I rotate the metal socket sleeve. Huhhh?

So cut the wires and take apart socket

Wow, the connection is by friction when screwing in the metal sleeve,

which is then poorly crimped to prevent rotation and getting loose when screwing/unscrewing

into the ceiling fixture socket. Fail!

How did the other made out? It did start intermittent flashing before finally quitting.

That one has only 3 screws covered in some caulking to prevent unauthorized entry :-)

Easily defeated for access. Not much room on the wiring

Single sided PCB,

Again nothing look damaged

Also fused, which also test short :-)

Founding nothing out of place, put it back together and tried.

It now start to flash again, but it seems to have a regularity to it.

Bad Capacitors??

Put them asides, I may or may not get back to it later. Very, very low priority...

Clearing everything of snow took most of Saturday, Sunday we were both tired and a bit sore.

We both took turns shoveling and snow blowing.

Not much happened in the shop, mostly putting stuff away...

and start making plans for next shop remodel projects, got some ideas percolating in the brain bucket.

Bob, who survived snow Armageddon 2022 part 2