Well.... I'm not so sure anymore, here's why

That tool, because of its sheet metal bed, versus the traditional cast iron bed, and sizes, is no doubt a Hobbyist, albeit well built, woodworking machine.

When I did a first quick search, I quickly zoomed in on Delta Homecraft products line, because they did HAD a sheet metal lathe in their line.

But trying to narrow it down better, I discovered an essential feature that the Delta had that mine does not: They welded spacer plate at regular interval, much like today, cast iron beds have such reinforcements casted instead.

In 1941 they replaced the steel bed with a cast iron one.

Delta No 930

Notice the closer gap on top of the steel folded bed.

Photo from Vintage Machinery.org

They also had a peculiar cast foot brackets to support and raise the steel bed up

Turns out, there was accessories cast foot to raise mostly metal working lathes to enable proper metal chips clearances. In woodworking, it is not so critical

So back to basic research to try to narrows it down.

Who else manufactured such Hobbyist power tools line?

One only has to look at giant retailers like Sears, Montgomery -Ward, etc to see a rather complete lines of woodworking power tools of different quality, at various price points.

North American readers are no doubts familiar with Sears's Craftsman tools lines, but they also used various Trade names for their "Entry level" tool lines

Companion

Dunlap

From a Craftsman tool catalog dated 1940

It sport very similar foots and although not mentioned, the bed look like it could be steel, which makes sense when reading down further: Shipping weight, 22 pounds! Trust me that is NOT a cast iron bed...

It also has bronze bearings (Bushing) with oil cupŝ, just like ours.

Numerous manufacturers made power tools for them, easily identified by the first 3 digits of the Sears code on the name plate.... when present :-)

Looking at them closer we find a very similar looking woodworking lathe, with the added pizzaz of streamlines on it, a nod to Art Deco from the 30's, marketed under the Dunlap name, and manufactured by a few makers

That very similar one, under the name Dunlap.

Most likely the same one, but could be a different manufacturers

Mine does not, but these "lines" were introduced in 1941 and were removed in 1949 (?)

Could it be my elusive lathe??

The tailstocks used a different adjuster handle, but mine is probably 50's ish, and it would be easier to cast a round handle, than the earlier spinning lever handle

Looking closer at it, I did found some cast marks on it, but still no name, nor model No, nor Serial Nos

In a circle it reads, with PAT in the middle:

GITS BROS

PAT

M.F.G CO.

On the oil bushing covers

.Well, look at that, turned out they are still in business

They were founded in 1910.

Lets have a look at what patents they got for these oil cup covers

Hum only patent returned when searching for oil cup...

Gits, Gits bros etc does not return anything under manufacturer.

Dead end for now... Could be a cumbersome search...

I did came across this patent assigned to Gits Brothers, but it is from the 70s so I doubt this is the one, besides it is not for an oil cup...

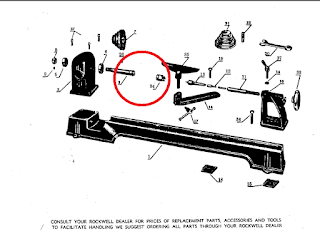

9JL-15

on the Banjo for the tool holder

9JL-6

Headstock

9JL-7

Tailstock

Given that the steel beds appears to be constructed more similarly than the Delta and al, and it does have the lub ports (indicating it used bronze sleeves versus balls bearings), I am now leaning more toward being a Companion/Dunlap machine and not a Homecraft.

Fold and welded construction.

Bottom is wide open, no reinforcement plates, no folded steel with holes, etc

Here is a short list of Companion/Dunlap made

The ones I have seen pics of often had the 3 digits manufacturers code followed by a dash and the rest of the model Nos on them

Frankly, I am temporarily stumped... Unless anyone else out there has a better guess?? Or more info??

Now trying to find more about these never seen before cast marks 9JL-X

That could be a rabbit hole I am going down into... But it also looks like my best bet to figured this out...

Bob, standing corrected.....until....