We are using the Taig micro lathe from LV.

See how I am hunched forward?

Holy cow where did my hair went to?? :-)

A sample of my Christmas gifts output that year :-)

Except... The lathe position is too low for me and it kill my back every time.

So when I had a chance to picked up a solid lathe for a good price, I got it.

It is a Rockwell Beaver. Made in Canada, 36 in Gap bed model 3400

It came with new bearings and paint job and a custom wooden stand.

Not a bad job, very solid and it has provision to ease belt re-positioning for changing speeds.

The motor is hung on a big hinge.

You pull down on this lever which has a big rounded bit at the end.

It push up the motor assembly, slacking the belts.

An attached bungee cord provides tension and the spring action

to return the arm up.

There is a rare earth magnet which hold the handle up.

Very ingenious system, could not have done better. Will keep it.

This lathe design has been around for a while. Originally under the Beaver name since 1938, but with a slight design difference.

Some of these older ones, used the ''about to become standard'' Morse taper system. Others, and later Rockwell, did not had a pierced headstock and did not support the Morse system, severely limiting its applications. But I suppose it was cheaper to manufactured :-(

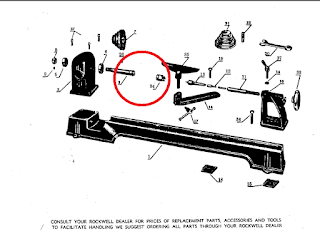

This old guy has an hollow shaft Headstock spindle (3) that accept a Morse taper Headstock spindle adapter (4) into which you thread the Headstock spur drive center (9). No 23 is a Headstock spindle draw bar, to ram the morse taper free if needed.

Same illustration, recycled in later years.

Mine does not have the hollow headstock, see (3) and (34)

It also used a bastard thread diameter and TPI combination on the headstock thread portion, 7/8-14 TPI. It is an orphan. So if only using the drive spur, you are limited to turn furniture pieces like legs, up to 36 in. Some models thru the years had a 16 inches bed extension, allowing to turn up to 48 inches.

Because of its gap bed you can turn wider pieces in the gap, and you can turn outboard to very large pieces. Not a bad lathe, heavy cast iron but too bad it does not support the Morse taper system. I have a few spares faceplates for bowl turning. They all thread in (7/8-14 TPI), except one is reverse threaded for putting on outboard turning. I also bought dedicated open ended wrenches of the sizes it required, 3/4 in, 1 in and 1-1/8 in, and a long time ago I found the Veritas center marking jig at a yard sale. Finally have a use for it :-)

Thankfully, the above limitations can be addressed with a 4 way multi chuck. Something sometimes referred to as a scroll chuck, like a Oneway Talon, etc.

Providing, I can get an adapter to interface the chuck to the lathe spindle.

Sure enough, turns out that most models of 4 way chuck used adapters and have one that fit my lathe.

Found this model on Kijiji for a good price,

just had to buy a new adapter for it.

Next I found that once mounted, I could easily grip my Pen turning mandrel sporting an adjustable Morse taper on its rod. Fit great on my lathe, I can now turn pens in my own shop and take care of that back problem, bonus :-)

OK, only remaining problem to solve is that the tool rest

is too wide to close in toward the mandrel...

But not so fast, what else do I need?

I need a center vise for my drill press. Not an absolute, could get by without it, but this make your job so much easier...

Model sold by LV shown. The beauty of such a vise is that once centered on the DP quill, it always centered your blanks perfectly no matter their sizes, up to the stated capacity of course. I have a bunch of special drill bits for various pen kits

Another way of doing it is by using a drill chuck on your lathe and just advance the stopped bit into the spinning object. That method also results in centered drilling.

Once you inserted the brass tube covered in instant glue, hopefully your fingers are not stuck to it...

See the missing piece of rubber on one of my glove's fingers :-)

I got a special tapered rod, a tool made to insert these various diameter brass cylinders into the wooden part with less chances of sticking your fingers and it is easier to seat them correctly. Inexpensive, but worth it

Once the tubes are glued, they have to be trimmed exactly square to each end same distance as the brass tube. If longer or shorter, pen kit components won't fit correctly. Again, there are a couple different way to do it, but I prefer using these tools, called pen mandrels.

You basically drill out square because of the long internal shaft, which is cleaning out any glue squeezed out that may have been introduced.

You go until you start to see shiny brass, stop!

They have various shaft diameter for various pen kits

Need a set of these to match my pen kits.

Of course, one need some chisels to turn anything, none came with my lathe.

I bought a full size 3/4 in roughing out gauge and a set of 3 pen turning gouges.

Once turned, the components need to be pressed fit assembled. Again, not necessary but a good pen press is a real time saver and avoid costly mistakes. don't ask!

This is the one from LV that's we got for the woodshop. I do not like it!

The screw lock mechanism is not capable to hold tight, so you end up over torquing the nut and bend the sheet metal lever...

This makes it probably the ONLY tool that I don't like in the whole LV catalog!!

This one, I got from my son Matt for a past Christmas.

Now that's a press! Easy to adjust, very solid and fast.

That's a keeper!

And that's it. It is all you really need to turn pens. Oh and I used my bandsaw to rough cut my pen blanks to size before drilling them.

Once I got a corner of my garage set up to turn, I will experiment with the correct height for me to turn safely without pain.

One last thing I picked up in prevision, is an easy way to maintain my turning tools. Got myself a Oneway Wolverine grinder jig, with the Vari-grind attachment. Will need to dedicate one of my two grinders to it in the garage.

Thanks again Kijiji :-)

So if you are looking for a good solid lathe to turn but have reservation about the lack of Morse taper etc, fear not. With the addition of a 4 way chuck, this lathe can now do it all, but for a lot less money. These lathes comes up often on the used market. Expect to pay around CDN $200 for such a lathe by itself, more depending on model and accessories with it. Low prices reflect perceived limitations, which has you have seen, are easily overcome.

A very good deal indeed to get into turning.

Bob, getting antsy to turn again...

Hi Bob,

ReplyDeleteI know how to use a lathe but it is one tool I have no interest in. If I need legs, Matthew Burak usually has something I can use. Maybe after I retire.....those pens sure do look like they make nice xmas presents.

I never really tried serious turning until about 6 years ago and that was on a pole lathe! Yes, my old OWA had organized a fun with pole day, so I went during my vacation, that was fun. I still got the kitchen spoon I made, and use it.

ReplyDeleteFast forward a few years and I tried my hand at pen turning.

I wanted a lathe big enough for furniture duties but nimble enough to do pen and other small objects. Have not tried it yet, but Im sure that setup should be fine.

Bob

I'll take some Windsor chair legs when you get a minute!

ReplyDelete😀

Sure Brian

ReplyDeleteAnd which June's day do you want them? :-)

Bob

Hi There!, I have some problems with my lathe, I don't know how i can remove the headstock spindle rockwell in this lathe 3400, can you help with that please, Regards

ReplyDeleteHi Mike

ReplyDeleteDo you mean as in removing the whole spindle out of the housing with the pulleys, or simply the screw in or morse taper 1 spindle, depending on its vintage?

Bob

Hey Bob

ReplyDeleteI was searching for pen turning on a Rockwell Beaver 3400 and hit your page. Imagine my surprise when I spotted the lathe my son restored and sold a few years ago!

He sold it to a fellow down towards Digby and that fellow must've sold it on to you.

My son was about 15 at the time and bought the lathe for $60 without a stand and it was just a pile of rust and the pulley's barely turned. He stripped it all down to bare metal, took off the name plates and got the pulley out. He put in new bearings and build the stand. He repainted the lathe and it was him that came up with that lever thing and the little block of wood for holding the tool rest on the outbound side. I think that little wooden steady rest came with it when he bought it, I know he didn't make that part. He did the wiring under my supervision and I helped him here and there but 90% of the effort was all his.

His name is Spencer and for some reason I think he signed the stand somewhere perhaps underneath.

Hope the lathe served you well. I almost bought it from him myself (he sold it for $270 to the other fellow if I recall), yours was so much nicer after he was done than mine is. His looked right off the factory floor except that tensioning knob on the tailstock.

Hi Garth

ReplyDeleteWell that is interesting, thanks for sharing.

I normally never keep the homemade stands that sometimes comes with vintage power tools, but in this case I made an exception, because it is well built and sturdy.

Good job Spencer :-)

I just look over the stand but did not find his name anywhere...

Bought it locally, Greenwood, from a guy who bought it a few years back but he never used it, hence why he sold it on Kijij for 250.

Rest assured it is back in service :-)

Thanks very much for the background history, appreciated

Bob

Hi Bob,

ReplyDeleteI have the same lathe as you, and for your mandrel, are you using an mt1 or mt2? I have the adaptor and scroll chuck, just wondering how to go about the tailstock with the saver. Thank you!

John.

Hi John, sorry for the late reply.

ReplyDeleteHere is the mandrel I used http://www.leevalley.com/us/Wood/page.aspx?p=46448&cat=1,330,43243,43245&ap=1

Because the headstock does not have an hollow spindle, I can only move in the mandrel rod so far inside the chuck. Not really an hindrance and it hold the pen mandrel solidly, centered, which are just what I needed.

Cheers

Bob

Thanks for your post Bob

ReplyDeleteI have the same lathe and your comment about the spindle was just what I needed to know. I now have the pen mandrel into a One-Way chuck and am all set to start turning out some pens.

Malcolm

You are welcome Malcom

ReplyDeleteEnjoy retirement :-)

Bob, retired since 2013

What an excellent and detailed breakdown of your pen-turning setup! It's always great to see someone finding creative solutions to overcome equipment limitations, and your modifications make that Rockwell Beaver a truly versatile lathe. Your passion for woodworking and pen turning shines through every step, from selecting the right tools to fine-tuning the workspace for comfort.

ReplyDeleteIf you're ever looking for high-quality exotic or domestic woods for your pen blanks or other turning projects, check out Exotic Wood Zone—they offer a fantastic selection that could add even more uniqueness to your creations. Keep up the great work, and happy turning! 🪵✍️