Part 1 The collector's models years. Type 1 to Type 7

Part 2 The user's models years. Type 8 to Type 19

This I intend to be a living document. I will update it as new or better photos and features becomes known or available.

Thanks for your help in this matter.

Most features are primarily as found on the No 4 Smoother planes. The No 5, 6, 7 and 8 planes being longer had their plane Nos cast at the heel versus the toe when Bailey appeared (in part 2).

No 1 is excluded, No 2 and 3 follow pretty well the same features except were the lack of room precludes some casting marks etc.

No 4-1/2, 5-1/4 and 5-1/2 falls somewhere in between, as they were introduced later along this type study.

Compiled from various sources on line, Notably from Walter, Leach and Sutherland. Pics are mine except as noted. Line drawings from Walter's book.

Text is based on original(s) with my own observations added. Rebuilt and updated Jul 16

Read this before using...

Wow, hard to believe I started this back in April...

TYPE 1 Boston Bailey 1867-1869

Trademark on Iron & Cap iron

Pics from Ebay

Solid brass Adj. nut has right hand tread. Early adj. nut may be two pieces construction. Name WOODS is always removed

Pic from Ebay

Lever cap is solid underneath and has a Banjo shaped spring

Pic from Ebay

Sides of planes are higher with the center of the round more toward the front than on later models.

Pic from Ebay

Bead edge at base of Rosewood knob

Pic from NH Plane parts

Rosewood handle (tote) has a distinct & graceful shape

NO Model Nos cast on bed

Top corners of frog are rounded

Round head screws (have a dome to it, later they would be flat)

hold the frog. You can see the screws in question on frog pic above

No 5 to No 8 sizes have squared edge on front of raised receiver for tote

Notice square receiver front under handle (tote)

This is a No 8 Type 2

Frog receiver is shaped like the letter I

Fillet cast on each side of high cross rib in front of mouth

TYPE 2 Stanley 1869-1872

All features of Type 1 except;

Early models of this type do not have Bailey's name on adj. nut

Most models of this type have Bailey's name on adj. nut

Spring under lever cap is now rectangular

No 4 Type 2

Pics from Ebay

No 8 Type 2, notice the bead detail on the front knob

Pics from Ebay

TYPE 3 Stanley 1872-1873

Major changes

All features of Type 2 except;

New trademark on irons

Pic from Bob Kaune

Center of the rounded sides is now further back

Special frog piece attached to a vertical rib

Probably designed by Bailey because it is similar to his "Victor' planes in Hartford.

A total redesign of the frog, where it became smaller and is held to the bottom casting by a vertical rib between the sides of the casting.

This feature has been observed on sizes from No 3 to No 8 only.

All frog pieces are of the No 3 sizes. This was probably an attempt to make interchangeable parts for most of the bench planes, instead of having a frog sizes to each size of bench planes. A lot of these planes are broken at the vertical rib so it was a weak design and it was soon abandoned.

Whether or not this was an experimental short run production has not been determined., however, enough specimens are known to warrant listing in this study.

This series of pics from Ebay.

Victor variant??

Adj. nut is now recessed. Bailey's patent date are stamped inside

Pic from Ebay

Lever cap now has a recessed back

Old style, solid in the back, on left

New style recessed in back, on right

Pic from Ebay

Fillet eliminated at base of cross rib in front of mouth, rib is now lower

Change in handle design

Major changes

All features of Type 3 except;

They are now equipped with the standard full frog as in type 2

Pic from Ebay

tip of Y lever is no longer rounded

Frog receiver is enlarged but still low and milled low. The number 73 is often cast in bed behind frog receiver is apparently just a foundry's casting code, because No 2 planes of same vintage have the number 71 cast there.

Still No Model's Nos

Pic from NH Plane parts

Flat head cap screw now used to hold the frog. They used to have a domed head, now flat.

Flat top frog screws make their debut

Pic from Ebay

No 5 thru No 8 have rounded edge in front of raised receiver for tote

No 5 Type 5

Notice the round end on the tote receiver in front

Pic from Ebay

TYPE 5 Stanley 1885-1888

Major changes

All features of Type 4 except;

New trademark on irons in later specimen of this type

Pic from Bob Kaune

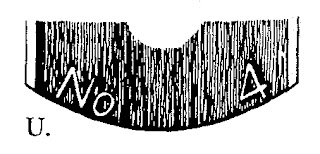

Model's Nos now cast on toe in front of knob. No 2 thru 8

Notice close spacing

No 5 thru 8 had Model Nos in front also

Pics from Ebay

Top corners frog are no longer rounded, the whole top is rounded

First lateral lever with patent date 2-8-76 and 10-21-84

Type 5 frog

Pic from NH Plane parts

TYPE 6 Stanley 1888-1890

All features of Type 5 except;

New style lateral with circular disk (two pieces construction)

Now with 3 patent dates 2-8-76, 10-21-84 and 7-24-88

Notice Pats Nos and were located

Pic from Ebay

Frog receiver has now two grooves cast across top in line with frog screws holes

Pic from Ebay

Model Number now cast with larger spacing

Bead eliminated at base of knob. Was there since Type 1

Sides wings noticeably lower

Changes in handle design

TYPE 6A Stanley 1891-1892

All features of Type 6 except;

New trademark on iron manufactured in 1892. That is the relocation of the hole from the top to the bottom of the slot

New iron design, where the circular hole is now located toward the cutting edge, instead of the top.

"The improved form of this

Plane Iron renders it unnecessary to detach the Cap Iron, at any time, as the

connecting screw will slide back to the extreme end of the slot in the Plane

Iron, without the danger of falling out. The screw may then be tightened, by a

turn with thumb and finger; and the Cap iron will serve as a convenient handle,

or rest, in whetting or sharpening the cutting edge of the Plane Iron."

There you have it, in all its gory, why the circular hole was re-positioned, after it being at the top of the blade for some 100 years. At least that's how

"Nib" casting marks on castings;

On bed just behind frog receiver

Underneath frog at front

Underneath lever cap

TYPE 7 Stanley 1893-1899

All features of Type 6 except;

Bailey's name and patent dates eliminated from adj. nut and cap iron (see Type 1)

Ad. nut in most planes of this type have left hand threads

Notice this is the first time we mentioned the Left hand threads rotation? That because it remained unchanged at being RH Thread since Type 1

What this mean is that "most" of all the brass recessed nuts with no patent dates should be LH Threads

Trademark with Patent date on all irons in planes of this type.

Spacing of number markings (E.G. No 4 to No 4) now one (1) inch

'S' markings on castings. Code letter for Session Foundry, subcontracted by Stanley for their castings. Found on bed, frog and sometimes lever cap, same locations as the raised dot . See Type 6A

END OF PART 1

Next part The users models, Type 8 to 19

Bob, taking a breather, that post was getting a tad long...

Dang Bob - that's a lot of work putting that together. Great pictures and great information. I'll have to bookmark this and the next post for sure.

ReplyDeletePicture 6

ReplyDeleteInteresting, with this you can mate the adjustment button with the Y lever to eliminate one source of slack.

Sylvain

Hi Bob,

ReplyDeletewow. This is once again a post with loads of information.

You have my full admiration. That is a lot of work and I'm always impressed how and were you got all this.

Cheers,

Stefan

Bob, Have you ever seen a lateral adjustment lever with the 1884 and 1888 patent dates only? My plane (seems to be a Type 6) has that but I've never seen that attribute mentioned anywhere. What do you make of this?

ReplyDeleteAlso, mine has anomalous body attributes according to your guide. It has the grooves in line with the frog screw holes like the Type 6 and after and the S foundry marks on the body, frog, and lever cap like the Type 7, but it has the closely-spaced No 5 label on the toe like a Type 5. It also has left-hand-thread brass adjustment knob with no labeling of the Type 7, but the Pat Apl 19.92 iron with the hole on the bottom of the Type 6A. Help!

ReplyDelete(It's a 5C by the way)

Hi anonymous.

ReplyDeleteWhat you described sounds like a Type 7, probably an early one.

Remember, when you read the Types characteristics, it most always started with “ all the features of previous types Except...”

Bob

Never heard of Type 5c but it could probably exist in a different type study?

Not nice that you copied Roger Smiths' type study info from Walters' book without crediting him for it.

ReplyDeleteAnonymous.

ReplyDeleteI beg to differ. I did state at the beginning that the info was mostly from him

Quote Compiled from various sources on line, Notably from Walter, Leach and Sutherland. Pics are mine except as noted. Line drawings from Walter's book Unquote.

As with any Type study on the subject you will find on line, most info came from Walter study, with a few more details gleaned from Leach and Sutherland. Pics are from Ebay or mine, source is always given. Not sure what you object to??

My contribution to those pionering work was to add visual pictures to better illustrated the various design changes. Something I long found missing, and why I did this post.

Bob, confused

Great work, Bob. Can you confirm I'm understanding the plane size correctly?

ReplyDeleteType 1-4: Absent

Type 5: In toe, narrow spacing

Type 6: In toe, slightly wider spacing

Type 7: In toe, much wider spacing

There are 3 spacing variations?

Sound about right, but will confirm later. Back from a town parade, long day.

ReplyDeleteBob, the Rotarian

Hi I found an old bailey plane in a bad state. And currently refurbishing it to use. The base plate has made in can stamped behind the frog mount. So far after inital cleaning it appears to be type 5 or higher. Any information about the made in can? Found in Nanton Canada in 100 year old barn clearout.

ReplyDeleteCheers Dave B

I managed to collect an entire set (2-8) of what I've decided to call type 5A. They have the two piece lateral control lever with the little roller like type 6, but they still have right hand threads, and the brass knob still has the patent dates in the recess. The frog seats are a mix of the types normally associated with Type 5 and Type 6. A reasonable guess to the factory dates is the winter of 1888-89. It took me three years to collect them all, and then I had two of the later fractional sizes machined to receive 5A frogs, so the set really is complete - it's nice when they all adjust by turning the knob in same direction. But now I have a complete set of Bed Rocks, which are all either type 1, 2, or 2A in the case of the 602. So the 5As have to go.

ReplyDeleteCongrats Craig, nice collection

ReplyDeleteHaving both Bailey and Bedrock, i can tell you that both are excellent workers, albeit the Baileys may need more fettling.

Enjoy

Bob

Hi Bob, Brett here from Australia. Did Bailey ever make a plane similar or same size as a #4 with NO size cast into the base, with ‘S’ cast behind the frog as in type 6. What is confusing is - no size numbers suggesting early type 1 - 4 BUT it has a lat. adj. lever low knob.

ReplyDeleteI have some pictures but cannot identify it. Unfortunately it is not in my possession but I am interested in buying it if it is an early Bailey.

Hope you can help

If pictures are required please let me know and I will send what I have.

Cheers

Possibly. The thing with Type study is that they are always a work in progress. What I publish is an amalgamation of pretty well everything I found plus my own observations. My contributions consist mainly of adding pictures to illustrate the points.

ReplyDeleteRemember Stanley and others never heard of type study down the road and were known to used up their parts inventory before switching over to new models features. As a results many tools do not fall nicely within Type boundaries. Add to that some parts may have been replaced thru the years (blades very often), repairs or unscrupulous dealers attempting to pass tools as a more valuable type and etc.

Again back to type study, it is believed that they started putting their models No starting at type 5.

Hope this help (?)

Bob