It looked unloved and had some issues, but when asked and he replied $5, it was love at first sight :-)

I also picked up a Canadian Champion BE chisel for a $1 and a MF block plane No 45 missing its adjuster for $5 from other vendors.

EC Atkins was a big player in the saws business, along with Disston and Simonds, as such all three made mitre boxes saws for other manufactures like Stanley and Millers Falls who made miter boxes but never made the saws.

The ones I came across the most with miter boxes or separated in the wild are Disston's, this is the first EC Atkins I came across.

It has a gently curved heel.

Nice touch, your hand will appreciate

Handle looks fine at first glance

The issues with it?

It has a damaged handle. There are split cracks at the bottom and a chunk is broken off the top horn.

See the fracture lines?

Must had been a hard blow.

I can push them apart

The broken top horn

Easy repairs. The saw plate is straight, but has a lot of rust, including some light orangery rust near the toe. Time for a rescue before its too late.

Orange colour is new rust starting

See the name stamped on the spline?

See some part of the etch?

Office is clearly seen and a few other part of words

Came apart easily, the saw nuts had to be punched out with a punch, they were tight.

There is a faint etch, so to protect it, I scraped this blade area only,

other parts saw the wire wheel on some stubborn areas.

The blade is clipped at the heel but looks like its a 22 in plate.

The tooth line stop at 21-1/2 in. We are not loosing any length, that area never see the wood

because of the saw posts

We got almost 5 in at the heel. Love the gently curved heel

And about 4-3/4 at the toe.

Canted blade or miss sharpen?

NO, the plate is sitting crooked in the spline.

The blade is straight, not touching it

Medallion has the Pat date of Dec 27 1887

There is a new site dedicated to Atkins saws, with lots of catalog info

From the 1906 catalog hand saw catalog, page 164

1906

Different stamp on the spline and no apparent etch

The replacement saw nuts and medallions.

They usually never sold you a medallion with their name on it,

but rather a Warranted Superior ones, like all other saw makers.

Pat date in question Dec 27 1887 for the Grover saw nut.

1919

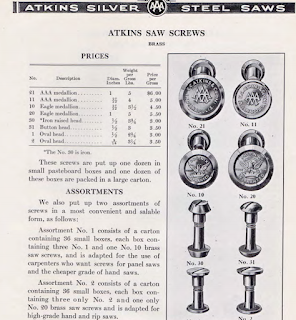

Ah? they are now selling their AAA Atkins spare medallion

1923 catalog

From the 1923 EC Atkins catalog No 19 , page 223 we find the following information on it:

We have a Mitre box No 1 Silver Steel saw, 22 in, 12 TPI with 5 in under the spline.

Handle is applewood

Etch area enlarged

By 1937 the handle is now beech, no longer applewood

and the back spline is blued steel

1950

Notice how the handle has changed

no longer as graceful curves

The last ones made, by Nicholson after their takeover.

Notice new etch. From 1967 catalog

So it would appear that my saw was made around the early 1910s-20s. Applewood is what we will be using to fix the horn.

First, we need to make a straight cut to make a strong bond. Once dried, the block will be shaped to match. What shape? If you look at any handsaw with unbroken horns, you will notice that the top and bottom horns are always the same length. That would be our starting point, and make it similar shape as the bottom one.

Just make sure it fit your hands right, providing the handle size is correct for your hands...

First was to fix the cracks. Titebond II for the large moving cracks,

Krazy glue soaked into the small hairline cracks around it to stabilized it.

Good as new.

For the horn, I need to established a squarer shoulder and flat surface

to glue in a block of wood

You can see the square area cut then split with knife chisel and rasp

with my donor applewood board

Let it dry for at least 24 hrs before starting to shape it.

There would be some stress on the glue line when shaping it.

Once my handle is done, I will re-assemble it and put it away until it comes out to play later on.

At which time it will probably be sharpened. The tooth line as is, looks pretty good.

For now, I have stopped the rust and took care of the problems on the handle.

That would make mitre saw No 6 in my till. Humm, I'm running out of room :-)

Bob, with a new problem on his hands, need a bigger, or another saw till :-)

Were you able to keep the etch visible after cleaning the blade? This is what I found the most difficult. I wish to find the secret recipe of etches revival :).

ReplyDeleteFor cleaning and polish to keep optimum visibility of an etch [or stamp on blades,] go to the Saws, using, collecting, cleaning and restoring Facebook.com [Group] at the top of Home page see Bob Page downloaded File -it has specific procedures for the best process.

DeleteMattjazz123.com

DeleteI have not yet finished cleaning the blade. I just scraped it with the razor, and wire wheeled some bad spots outside the etch area.

ReplyDeleteIt is hard to see, but it does not looks like I erased anything yet...??

Later I will give it a light sanding, with a hard block, to protect the etch area. I too wish for that miracle recipe, but so far As long as some parts of the etch are visible Im happy, but whish to proceed carefully on the next moves, sanding, autosol etc. If it resuscitate the etch, I'll blog about it for sure !!!

Bob, the eternal optimist

An fascinating discussion is value comment. I think that it is best to write extra on this matter, it won’t be a taboo topic however generally people are not enough to talk on such topics. To the next. Cheers https://bestmitersawguide.com

ReplyDeleteKeep it up, You can use a miter saw that we already have a Top review on.... The miter saw these are great and best, make your decision to read The review. Thanks!

ReplyDeleteGreat article, thanks for sharing this info, If you want to buy miter saw then I recommend you to visit this site https://mywoodgear.com/best-miter-saw-for-furniture-making/..

ReplyDelete