Diversion No 35 and we are only in early March. Ok I exagerated a bit, but you get the idea :-)

Our newly wed Son, wife and grandkids are coming for a visit soon, exciting, but of course it necessitated (??) some more re-org around the house. Currently working on a project inside garage. Turning a mess in one corner into an organized and tidy spot. That would free up lots of spaces inside and long overdue also 😁

The area in question. A long standing issue has always been

the lack of a platform on top of stairs in front of door.

That area was also covered in wood stash, removed in this pic.

The wood relocated from that space.

The plan is to build a platform in front of the door entrance to the house, move the stairs, build a storage grid for large plastic containers. The grid will hold 9 containers, plus a few more large ones under the platform.

That project has been on my radar for a while, but the problem always been, how to bring lumber home in the Spark... not much...

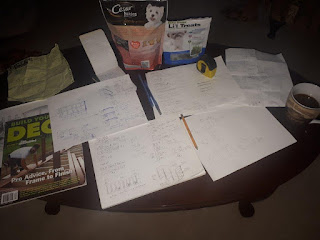

Plans taking shape.

Revision 3 or 4? in progress.

Spend a day making plans, went to the lumber yard with my truck, everything fit with room to spare .

I can even lay flat a sheet of 4X8 between the wheels well, I'm in heaven. So, so much easier and no $50 delivery charges regardless of load. (which probably went up or will soon with quickly raising gas prices)

Talking of gas prices, found out I had a fuel leak when filling up the truck, had it fixed, $1500 later . Cannot have gas leaking in my driveway, the house water well is up front.

That should be quickly repaid in gas savings with the price of fuel going up quickly 😏

So much easier than with the Spark (insert big grin)

The 12 footers, I had cut at the lumber yard to 128 inches

That little pile is about Cdn $300, ouch!

Two 2x6x12, seven 2x4x10, two 4x4x8 and eight 4 inch spruce strapping boards.

Was surprised my estimates was higher than what I paid. Back home quickly figured out that would be because I forgot two 2x6x10 and one 2x4x10, oops.

I had so many plans changes, I got confused.

My story, sticking to it... Scrounged some more pieces of 2x lumber around the house, said pile is getting smaller.

Went back yesterday, bought my two 2x6x10, for the 2x4, I used the two I was using to prop the greenhouse up. No longer required, made some mods and she is holding up fine to the winds, snow and ice. We put one of her 2 portable greenhouses inside, inside which I build a heated germinating bed. Currently in use and working great.

Not trusting the bent frame to hold up to snow loads.

The other side, shed its snow easily, that side not so much.

Portable greenhouse inside plus metal plant stand inside should offer enough protection.

Has not been an issue so far, we do clear the snow as required.

Very impressed on how tough greenhouse plastic is.

I will take it apart and rebuild it stronger, after the new one is up beside it.

Using the Veg-Trug frame and cover over the warning bed.

That green house inside a greenhouse, inside a greenhouse, is doing the trick.

Temps can reach 27C in the noon sun even with below zero temps outside.

We monitor remotely temp and humidity inside.

Seedlings are growing happily inside.

Also picked up my hardware, following multiple revisions to my platform. I am also using it as a dry run for building my new rear deck this summer. I am building a small 10 ft long deck 40 inches wide bolted to the inside wall of garage and supported by three 4x4 post up front. Platform frame is built of 2x6 lumber, 16 inches On Center (OC) to be covered with 3/4 inches plywood. No doubts overkill, but Par for me.

I am using a Fine Homebuilding magazine.

Build your own deck as a reference and with help from Rudy.

Don't forget space for my monkey Dad.

Reading thru it made me make some design changes.

My biggest challenges so far has been making the room to work in. Only got so much spaces to put all that stuff that was in the corner, somewhere else. I am then working in a cramped space on the floor in the space free up for the platform, it`s cold and I am cramped. Suck it up and get to work.

Figuring out the space I need and checking my measurements

to ensure everything fit as I envisaged.

That should do it.

Deck block in front are just holding up the board.

They would be under the front beam

That also dictate how I am going to assemble and put up such a frame up in the space. My latest plans, is to bolted the ledger to the house, level up the 4x4 posts up front to the back ledger then drop in the joists in the hangers. Once that platform is up I will use it to assemble the 9x9 grid. Said grid will be resting on top of platform secured by two French cleats on the wall, so I can removed it later in the Spring when it would be warm enough to paint the wall behind it.

Cut three posts at 25 inches, they are resting up on the block which add another 6 inches.

That makes up the final maximum height of 30 inches which is just under the door.

The line I draw on the wall is at 30 inches, Final rough height will be 1-1/2 in lower.

Removed stairs, cut gyprock 1-1/2 inch lower around the area to exposed studs.

The wall is covered in boards, as was the norm before using plywood or OSB now a days.

But I must screw into the studs. More detective works required.

Lined up both ends of my ledger and beam, ensuring they are square and same length.

I had them cut at the lumberyard to 128 inches.

Then it was only a matter of laying out my marks on both beam at once.

The black line behind is plastic roofing cement from a caulking gun.

There was a gap between the cement floor and the wall footings.

That was the only thing I found suitable that could be applied in the cold.

Then fasten my hardware, ensuring they lined up

Using special end hangers on each ends and regular 2x6 joist brackets.

This is where I stopped last nite. I am sore from working in my cramped space on the floor and the gymnastic required to go up and down inside garage door without steps. Put up a small stool step, but it is still a good exercise routine :-)

Today the plan is to fasten the ledger board, figured out my final front posts dimensions and add the 37 inches joists (9) and I should have a platform.

My bright original plans was to put 3/4 inch plywood on top then 1/2 inch plywood on each cubicles of the storage grid. That would be 3 sheets of plywood if I used the same thickness everywhere or two 3/4 sheets and two 1/2 inch sheet. About Cdn $200 of plywood for 3 sheets, gulp.

Revisiting that plan by looking at what I got. Found a few large pieces of 3/4 in plywood, so will covered the exposed platform. The space under the grid, I am thinking of salvaging some of the decking boards from the old rear deck, which is going down this summer.

Cleared the never ending snow off the rear deck

to measure how many boards would be required.

11 pieces across will do it.

I have lots of pieces already, but they are currently under snow, sigh! For the plywood on the deck I am thinking of covering it with vinyl weather proof laminate. I have a box of left over. A box cover 24 Square feet, I need 22.5 square feet. Other plans this year is to remove carpet in living room/dining room and replaced with hardwood or engineered wood and the area by the computer office, which has a door to the rear deck, with that vinyl planking. Would see what happens when I get there.

Bob, working away on the house. Wood shop downstairs is taking shape, Man cave space all cleared and ready for the kids entertainment. Should be all done in time for the kids visits :-)

Now to go cleared more "$%& snow before the next one within 24 hours. Will it ever end??

No comments:

Post a Comment