As you read this, it has started around the world, but let me whishes you all a new year fill with health and happiness.

At this time of the year it is also a good idea to look back at what we accomplished and start making plans (some call them resolutions :-), for the upcoming year.

So lets see how I made out with my last years plans

Fix that small drone for my son.

Nail it! Bought a new one :-)

Finishing my Boring till.

Finally done! Only took two years...

Also made a boring bit till to go with it

Install a 6X6 beam in my shop for installing my post drill.

Post has been up temporarily (still need to be fastened)

Waiting for it to finish its stupid wood tricks (acclimatized to my shop)

Rehab Post drill.

Not much progress on that one... De-gunking it will be very messy,

I need the right weather to do it outside.

Works with my son on his projects.

We managed to fit three in his busy schedule and have a few more in the planning stages

Survey my son's tool kit inventory and start building storage boxes

A work in constant progress, should be able to finished it in 2019???

Built a bigger dining room table & chairs

Nope :-( That one is a carry over numerous years. Must get Round-to-it

Built two more garden tools storage stations

Never did happened, got close to another but it ended up as a bird house instead :-)

She also wants some squirrel feeders, bat house and more bird houses

Make some progress rehabbing my ever growing piles of rusty objects.

Getting there, but it is an uphill battle :-)

Did experiment with my first complete strip and repaint restoration (BBM) and metallic brushes (wire wheels). As a result I have upped my game doing restorations.

Install new windows in garage

Done, but still need to finish inside. Insulate, wall covering, trim

Bring in 220V in garage

Another long standing want, ever since moving here. Keep getting push back in priorities.

We are planning to move laundry room upstairs (again, was first planned with Heather), that will necessitate bring in 220V in garage, yeah :-)

Make more progress decluttering garage

A never ending process, some goes out, more comes in... :-)

Install new bath fan in ensuite bathroom

Overdue, but I need to right weather to go inside attic, too damn hot in summer

Demolish and built a new deck

First we had to cut down the leaning tree in front of it (done) then we measured out and start plans for the deck. After the initial sticker shock for the estimate, decided to proceeded in 3 phases.

Built first level, then lower deck, then add the structure on top of main level.

Hoping to get to the first phase this upcoming year

Replace flag bracket up front

Done. This time using a cast iron bracket, hoping it will last longer...

More backyard projects

In prevision for cutting down a few trees around the properties, built a bigger and proper fire pit to burn the resulting branches etc.

The earth removed was used to created a new garden plot by our fruits gardens

Numerous trees were cut around my property line in prevision of building a fence in the back yard.

Others were removed for being to close to the house and in the way of future projects.

More new trees and bushes were transplanted or added

A new driveway has been planned to provide heavy machinery and delivery of material in the back yard. Ouch, not cheap! :-(

A spot has been cleared and made more "level" for the upcoming greenhouse and outdoor dining room.

An if you think that all of this is going to be expensive, you should see the estimate to paved my existing driveway !! Ouch, that will go to the bottom of the list, unless I win at the Lotto :-(

Probably would have more luck if I was to buy tickets? :-)

SO... what in store for 2019?

Not much, just finished what I started this year :-)

First is that small hall table for her sister. My hang up are the two rear legs, need to make yet another pair, sigh

Install that bath room fan

Bring in 220 V in garage and move laundry room

Catch up with some minor maintenance issues around the house

Start new driveway, get at least the culvert done

Get new deck started hopefully

Replace back sliding door by French doors or replace the two garage doors? Both if it fit my budget

Anything else I manage to get off my list would be gravy :-)

Now off to update my infamous Excel spreadsheet of work to do

Bob, making resolutions to finished 2018 resolutions, started in 2017, which were planned in 2016 following 2015 resolutions... Or something like that :-)

Monday, December 31, 2018

Monday, December 24, 2018

Merry Christmas around the world

I know my keyboard's dribbles are read around the world and I also know that not everyone celebrate Christmas, some even find it offensive and want us to say happy holidays instead.

This is not about religious beliefs, this is simply a yearning to find peace and solace for at least one day and reflect on this crazy humanity that we are.

I am an old warrior, no one yearn peace more than a soldier because we only do fight so others may live in peace.

So tonight, if you can, surrounded by family and friend, whomever you are, wherever you are in this crazy world of ours, take time to reflect on a possible peace miracle... If you believe...

Sadly after all these years of co-existence on this planet, we have yet to figured out that we are all, not so different than each others and cynically, more wars amongst ourselves has been fought under some religious pretense.

A true God under any name does not condone war under any pretexts.

End of polite Canadian international rant, we now return to normal woodworking in progress.

Well, a Christmas tree is wood, so that count as woodworking right? :-)

Bob, the old Santa

This is not about religious beliefs, this is simply a yearning to find peace and solace for at least one day and reflect on this crazy humanity that we are.

I am an old warrior, no one yearn peace more than a soldier because we only do fight so others may live in peace.

So tonight, if you can, surrounded by family and friend, whomever you are, wherever you are in this crazy world of ours, take time to reflect on a possible peace miracle... If you believe...

Sadly after all these years of co-existence on this planet, we have yet to figured out that we are all, not so different than each others and cynically, more wars amongst ourselves has been fought under some religious pretense.

A true God under any name does not condone war under any pretexts.

End of polite Canadian international rant, we now return to normal woodworking in progress.

Well, a Christmas tree is wood, so that count as woodworking right? :-)

Bob, the old Santa

Me arriving as Santa for the kids at the WO & Sgt mess in 2008

In the back the crew is yelling at me: Stand in the door and wave at the kids.

Me: Holding on the door frame for dear life: They cant see me, it's all white :-)

A tad windy too, I recall... Heather lost her mitts taking that picture.

Santa Bob, tested by the "kids" See it's real :-)

Yes, boys and girls, Santa wears Canadian Army boots :-)

And when he enter the Canadian airspace he is protected by the RCAF,

while the RCN gave him picket coverage has he crossed oceans to get here.

MERRY CHRISTMAS EVERYONE AND TO ALL PEACE ON EARTH

Saturday, December 22, 2018

RH Smith small tenon backsaw

I would had normally include its history here, but it was a tad convoluted, and I ended with a post on the saw makers gang instead...

So here is the little saw that started that last post, while researching it

We know that RH Smith started in 1870 by buying J Flint saw works in St Catharines On.

They were bought by Shurley Dietrich in 1893 then operated under that name until 1914

when it was changed to TF Shurly Co.

The patent date is telling us that this saw would had probably been made between 1887-1914.

Patents last about 17 years back then, so that script about the patent would had been gone no later than (1887+17= 1904) Early 1900s would be my best educated guess, judging from the beaver on the medallion

Looks like a poor candidate? Au contraire, looks marvelous....for its age :-)

Unscrewed the handle, scraped then sanded the saw plate, paying attention to the saw back also, but being very careful not to erase the faint etch I saw on the plate. Very hard to impossible to photograph, but its there all right.

I scraped then sanded the handle, then gave it two coats of Howard Restore A Finish, golden oak

Once dry, wiped then hand buffed a coat of Howard Feed N Wax.

The handle really pop back to life and I'm happy with the coloring imparted, just about right.

The final look for now. Blade has been given a wipe on coat of WD 40 to protect it.

Like I said the saw tooth is in very good shape, it cuts pretty good as is, but it will eventually get a tuned up. She is a keeper

Bob who has a seemingly never ending pile of tools to restore...

Go figure :-),

So here is the little saw that started that last post, while researching it

The vendor had identified it as a St Catharine saw from 1887, based on the medallion.

I paid Cdn $20 for it and was quite happy :-)

It is not from 1887, that patent date is for the Glover saw nut, used by many makers

They were bought by Shurley Dietrich in 1893 then operated under that name until 1914

when it was changed to TF Shurly Co.

The patent date is telling us that this saw would had probably been made between 1887-1914.

Patents last about 17 years back then, so that script about the patent would had been gone no later than (1887+17= 1904) Early 1900s would be my best educated guess, judging from the beaver on the medallion

Tenon backsaw from Shurly-Dietrich 1902 catalog,

who was operating the St-Catharines plant at this time

Looks a bit rough, but it fits my hand perfectly... like a glove

The plate measure 12 inch long X 2-3/4 inch deep

Making it a small tenon saw

There is some green paint remains on the handle,

The saw plate and the steel back have lots of superficial rust on it.

The teeth line is amazingly in good condition, filed at 11 TPI

The top saw horn has a small chip, but its location

does not affect its handling in the hand.

If I ever fix it, I'll just graft a new piece of wood and shaped it

Looks like a poor candidate? Au contraire, looks marvelous....for its age :-)

Unscrewed the handle, scraped then sanded the saw plate, paying attention to the saw back also, but being very careful not to erase the faint etch I saw on the plate. Very hard to impossible to photograph, but its there all right.

I scraped then sanded the handle, then gave it two coats of Howard Restore A Finish, golden oak

Once dry, wiped then hand buffed a coat of Howard Feed N Wax.

The handle really pop back to life and I'm happy with the coloring imparted, just about right.

The final look for now. Blade has been given a wipe on coat of WD 40 to protect it.

Not bad for a 100 years old plus saw

Like I said the saw tooth is in very good shape, it cuts pretty good as is, but it will eventually get a tuned up. She is a keeper

Bob who has a seemingly never ending pile of tools to restore...

Go figure :-),

Wednesday, December 19, 2018

The saw makers gang of Joseph Flint

Joseph Flint left England for America to start a saw making works in New-England.

Just like we saw in the history of plane making in Canada, other trained tool makers, both American and British, emigrated to Canada and established themselves, and would be Canadian tool makers went to both America and/or England to learn their trades.

Accordingly, and not surprisingly, one of the first recorded established saw maker in Upper Canada (today's Ontario) was that same Joseph Flint, now of Rochester New York. He operated a saw making business in Rochester from 1844 to 1888.

The Pat date on it is Dec 31 1867.

That was a patent on saw nuts. This design is rather fragile, careful when attempting to remove these saw nuts. Notice it still used a split nut

Among the workforce in Rochester NY were: RH Smith, Jerome C Dietrich and Cosmos J Shurly

Jerome C Dietrich was born and raised on a farm near Rochester NY. He entered the saw works of D.R. Barton of Rochester NY . In 1866 he became a traveller for J Flint Co. After being offered another job elsewhere, his employer countered with a raise and part ownership. As a result of a later disagreement, he sold his ownership and left with Cosmo Shurly to start The Maple Saw Works in Galt. In 1877 he invented the Lance tooth crosscut saw, which was reputed to be the world's fastest and shipped around the world.

RH Smith bought the J Flint factory in St-Catharines in 1870

The patent date of Dec 27 1887 is for the Glover saw nuts patent. A much more robust saw screw, easier to manufactured (not cast but stamped) and has ribs to prevent rotation. It would eventually displaced the Disston screw version and became the defacto standard to this day.

Cosmos Shurly married J Flint Daughter. In 1873, Shurly and Dietrich moved to Galt On (now Cambridge) to start their own saw works, The Maple Leaf Saw Works. They were established in an old tannery building which belongs to Goldie & McCulloch Foundry.

They started with 9 saw makers from both Rochester NY and Sheffield England.

by 1886 they employed 70 skilled workers.

When RH Smith retired in 1893, Shurly & Dietrich assumed full control of the company.

In 1914, this business was renamed the T.F. Shurly Company, and was operated by Cosmo Shurly's son Theodore. It will continue until the 1920s.

At the turn of the century, logging was big business in Canada, this in turn fueled a high demands for axes and saws. Shurly & Dietrich earned a good reputation for the quality of their steel. Their saws commanded a large part of the logging market.

By 1906, Cosmo Shurly son's Theodore was the factory superintendent.

Between 1909 and 1910 Shurly & Dietrich expanded its original factory in Galt On.

In 1914, the Galt factory sustained damages in a fire, but by that time, they had another plant in St-Catharines On (the TF Shurly Company, which was the previous RH Smith who bought J Flint).

Beginning in 1910, the big American saw maker E.C. Atkins (established 1857) opened a factory in Hamilton On.

Coincidentally or not, that is at the same time frame that Disston went to Toronto, and Simonds in Montreal... (AKA going around Tariffs :-)

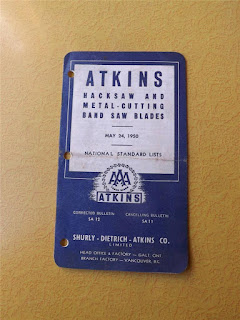

In 1931 Shurly & Dietrich merged with the E.C. Atkins of Hamilton On, becoming Shurly, Dietrich & Atkins. Meaning essentially that SDA became the Canadian branch of the American EC Atkins.

At, or around this time, the Hamilton plant closed and the machinery relocated to the Galt plant.

They opened a branch factory in Vancouver BC in 193x (?)

SD, then SDA, was a long established maker of refined, silver (steel) and cast steel. Having developed an expertise in hardening and tempering steel, they were tasked with producing 40,000 tons of light armour plate during WW II.

By 1957 they were one of the two major saw makers in Canada (the other one being Disston)

By 1968, about 1,400,000 feet of bandsaw blades, for cutting metal, and over 1,000,000 jig saw blades were being manufactured each year.

In 1969, SDA was acquired by HK Porter (who also acquired Disston in 1955) and lets be honest, HK Porter did a fine job running both Disston and SDA...into the ground !!! :-(

In 1973 they would close the plant in Galt (Cambridge) after one hundred years of operation.

So there you have it:

RH Smith, Cosmo Shurly and Jerome Dietrich were working for Joseph Flint in Rochester NY making saws (operated 1844-1888).

Joseph Flint opened a saw works in St Catharines On in 1855

RH Smith bought the Flint works in St-Catharines On in 1870

Cosmo Shurly married Joseph Flint daughter

Cosmo Shurly and Dietrich start the Maple Leaf Saw Works in Galt On in 1873

Shurly and Dietrich take over the St Catharines plant of RH Smith when he retired in 1893

In 1906 Theodore Shurley, son of Cosmo, is the Superintendent of the Maple Leaf Saw Works

In 1914, the St Catharines plant is renamed TF Shurly Co and Theodore is running the company (it will last until the 1920s)

in 1931 Shurly Dietrich (SD) merged with EC Atkins and becomes Shurly-Dietrich-Atkins (SDA)

In 1969 they are bought by HK Porter who will close the Galt plant in 1973

The end

Hope this get the story straight, there is a lot of confusion with dates on line, as I found out...

As usual, errors or omission's, let me know.

Bob, overdue for a cold one

Just like we saw in the history of plane making in Canada, other trained tool makers, both American and British, emigrated to Canada and established themselves, and would be Canadian tool makers went to both America and/or England to learn their trades.

Accordingly, and not surprisingly, one of the first recorded established saw maker in Upper Canada (today's Ontario) was that same Joseph Flint, now of Rochester New York. He operated a saw making business in Rochester from 1844 to 1888.

J. FLINT

CAST STEEL WARRANTED

ROCHESTER

The "label" is not chemically etched, but stamped, as earlier saws plate were

Pic from Backsaw.net

Advert from 1879

153 State street, Rochester NY

J. FLINT ROCHESTER N.Y. medallion

Pic from Canadian Woodworking online Forum

J. FLINT SUPERIOR medallion on a handsaw

Pic from Canadian Woodworking online Forum

The Pat date on it is Dec 31 1867.

That was a patent on saw nuts. This design is rather fragile, careful when attempting to remove these saw nuts. Notice it still used a split nut

DATAMP screen shot

Notice the Dietrich wood saw patent and the Dietrich patent 2 hands hold saw

Among the workforce in Rochester NY were: RH Smith, Jerome C Dietrich and Cosmos J Shurly

The 1872 double handle patent to Jerome C Dietrich,

witnessed by Cosmo J Shurly

DATAMP screen shot

Here is a picture of two examples, of which only 3 are known...

Photo credit on pic

Jerome C Dietrich was born and raised on a farm near Rochester NY. He entered the saw works of D.R. Barton of Rochester NY . In 1866 he became a traveller for J Flint Co. After being offered another job elsewhere, his employer countered with a raise and part ownership. As a result of a later disagreement, he sold his ownership and left with Cosmo Shurly to start The Maple Saw Works in Galt. In 1877 he invented the Lance tooth crosscut saw, which was reputed to be the world's fastest and shipped around the world.

JC Dietrich residence in Galt (Cambridge) Ontario.

Apparently there is money in saw making...

J. FLINT

CAST STEEL St CATHARINES WARRANTED

on a back saw steel spine

Pic from Canadian Woodworking on line Forum

J. FLINT

St CATHARINES

CAST STEEL WARRANTED

Pic from Canadian Woodworking on line forum

RH Smith bought the J Flint factory in St-Catharines in 1870

RH SMITH & CO Ltd

PAT DEC 27

1887

St CATHARINES

. RH SMITH & CO.

PAT DEC 27 1887

St CATHARINES

The patent date of Dec 27 1887 is for the Glover saw nuts patent. A much more robust saw screw, easier to manufactured (not cast but stamped) and has ribs to prevent rotation. It would eventually displaced the Disston screw version and became the defacto standard to this day.

DATAMP screen shot

Cosmos Shurly married J Flint Daughter. In 1873, Shurly and Dietrich moved to Galt On (now Cambridge) to start their own saw works, The Maple Leaf Saw Works. They were established in an old tannery building which belongs to Goldie & McCulloch Foundry.

They started with 9 saw makers from both Rochester NY and Sheffield England.

by 1886 they employed 70 skilled workers.

Sequence of apparition.

The beaver was a left over from the St-Catharines factory (post 1893),

the maple leaf appeared after they transition all production to Galt On (early 1900s).

They were one of the first company to use Maple Leaf and Beaver as a Canadian identity

When RH Smith retired in 1893, Shurly & Dietrich assumed full control of the company.

In 1914, this business was renamed the T.F. Shurly Company, and was operated by Cosmo Shurly's son Theodore. It will continue until the 1920s.

The Arrow Head saw, made previously by RH Smith

continued to be made under TF Shurly, then SDA

Pic from link above

Shurly & Dietrich manufactured and patented a whole range

of saw maintenance tools for the logging industry

By 1906, Cosmo Shurly son's Theodore was the factory superintendent.

Between 1909 and 1910 Shurly & Dietrich expanded its original factory in Galt On.

In 1914, the Galt factory sustained damages in a fire, but by that time, they had another plant in St-Catharines On (the TF Shurly Company, which was the previous RH Smith who bought J Flint).

Beginning in 1910, the big American saw maker E.C. Atkins (established 1857) opened a factory in Hamilton On.

Coincidentally or not, that is at the same time frame that Disston went to Toronto, and Simonds in Montreal... (AKA going around Tariffs :-)

In 1931 Shurly & Dietrich merged with the E.C. Atkins of Hamilton On, becoming Shurly, Dietrich & Atkins. Meaning essentially that SDA became the Canadian branch of the American EC Atkins.

Older EC Atkins medallion showing the Dec 27 1889

Glover saw nut patent, same as used by RH Smith and SD

Pic from eBay

from

At, or around this time, the Hamilton plant closed and the machinery relocated to the Galt plant.

They opened a branch factory in Vancouver BC in 193x (?)

The SDA plant on 30 Mar 1935

1642 Richards St Vancouver BC

Archives city of Vancouver, Public Domain

SD, then SDA, was a long established maker of refined, silver (steel) and cast steel. Having developed an expertise in hardening and tempering steel, they were tasked with producing 40,000 tons of light armour plate during WW II.

Maple Leaf No 460 precision web saw jointer

These two pics Ebay

SDA 1950 salesman manual

This being a salesman manual, it has instructions

on what to ask if you have to "adjust" complaints

The plant at 17 Glebe St Galt Ontario

as it appears on the back of 1950 booklet

These pics from EBay

By 1968, about 1,400,000 feet of bandsaw blades, for cutting metal, and over 1,000,000 jig saw blades were being manufactured each year.

Jig saw blades packages from

Shurly-Dietrich Atkins Co Ltd

Galt Ont

Pic from Progress is fine blogspot

In 1969, SDA was acquired by HK Porter (who also acquired Disston in 1955) and lets be honest, HK Porter did a fine job running both Disston and SDA...into the ground !!! :-(

In 1973 they would close the plant in Galt (Cambridge) after one hundred years of operation.

So there you have it:

RH Smith, Cosmo Shurly and Jerome Dietrich were working for Joseph Flint in Rochester NY making saws (operated 1844-1888).

Joseph Flint opened a saw works in St Catharines On in 1855

RH Smith bought the Flint works in St-Catharines On in 1870

Cosmo Shurly married Joseph Flint daughter

Cosmo Shurly and Dietrich start the Maple Leaf Saw Works in Galt On in 1873

Shurly and Dietrich take over the St Catharines plant of RH Smith when he retired in 1893

In 1906 Theodore Shurley, son of Cosmo, is the Superintendent of the Maple Leaf Saw Works

In 1914, the St Catharines plant is renamed TF Shurly Co and Theodore is running the company (it will last until the 1920s)

in 1931 Shurly Dietrich (SD) merged with EC Atkins and becomes Shurly-Dietrich-Atkins (SDA)

In 1969 they are bought by HK Porter who will close the Galt plant in 1973

The end

Hope this get the story straight, there is a lot of confusion with dates on line, as I found out...

As usual, errors or omission's, let me know.

The saws from my till that were used for some pics.

Some RH Smith, some SD, but could not find any of my SDA saws??

The material used to cleaned up the medallions.

Yes, some were consumables :-)

Bob, overdue for a cold one

Sunday, December 16, 2018

Progress on a few fronts

The last couple days been helping a friend with his Christmas project for his wife.

Can't tell you what it is, it's a surprise :-)

Yesterday, end up at the wood shop from 10AM until 4PM, a long day, so I brought along a few tools rehab projects.

First up was my BBM crank handles refinishing

Long overdue, but very low on my priority list. But its a quick job and it is taking room in the shop.

So out it came with me

Can't tell you what it is, it's a surprise :-)

Yesterday, end up at the wood shop from 10AM until 4PM, a long day, so I brought along a few tools rehab projects.

First up was my BBM crank handles refinishing

Long overdue, but very low on my priority list. But its a quick job and it is taking room in the shop.

So out it came with me

Long overdue, it really makes a big difference

using a walnut stain, blending in the blemish and repairs

The next day, I gave it a coat of feed N wax

I really like the final look

An old Smith of St-Catherine On. back saw got a quick clean up

A light scraping, sanding of the plate, followed by a wipe of WD40

The handle got a scraping, need a light sanding before being re-finished.

There is a very faint etch I want to preserve

The hardware as removed, before its bath at home

Last time I used it, I noticed a bit of rust was forming on both faces

of my world famous Je Ne Sais Quoi Persuader, all the way from Namibia.

Gave it a light sanding to clean up the faces

What took me the longest was to shape my handle to fit inside

the eye of my Campbell Hewing or Ship axe

As you can see it was still a tight fit

Before wedging

I am happy the way it came out

Now if I can just find my wedge kits ???

I have been working for a while on a Bailey Tool Co smoother

Body and parts have been de-gunked, de-rusted, started

to address the sole and the blade

And yes that blade is pretty well used up

Also brought out a chisel to touch up along with a few other tools for my friend to use on his project

That was the scene Dec 10 in my yard.

In the last two days, it is pretty well all gone, but another storm is coming to replenished it.

That storm should be over Ralph as I type this

Accordingly, I better pick up my small logs to split before they get covered again.

Forecasted up to 10 Cm of white crappola (Ralph's Tm)

And next thing you know, it was time for a visit to the WComd at home event as the Vice President of my Rotary club, so signing off

Bob, making progress on a few small fronts

Subscribe to:

Posts (Atom)