Been a tad busy around here at times. The Greenhouse is still standing but took a hit from a big pine which totally flatten the new metal shed I was in the process of installing and almost killed the plastic shed behind also, I think I can salvaged it, got some ideas, but it will have to wait.

The 10X8 metal shed we just had moved from her property to our place

And the plastic Rubbermaid shed behind it were supposed

to contain all the various plants pots she has.

And if you were thinking that is a lot of pots, that was also what I first thought so I asked her if she needed them all. She replied: Do you need all your tools?

Obviously, we are going to need a bigger shed :-)

But helas, a big bad tree had other ideas. We don't often get winds from the south, but it does happened.

The greenhouse survived, the metal shed is scrap, the plastic shed,

I'm thinking I may be able to recovered?

Want to try warming up the piece and try to pop it back in place??

The metal shed crumbling under the tree probably helped saved the greenhouse by absorbing most of the impact

Inside afterward. The plastic held up, the metal frame not so much

Was able to gently push most everything back up.

Space is useable, everything that could get damaged has been removed.

The two wood framed ends held up, the back one experienced some twist, but resisted.

The only broken piece is one of the upper support.

Needless to say, I have ZERO confidences in that metal frame anymore. My plan is to make new hop by bending tubular steel pieces I'm gathering. A project for Spring.

Meanwhile will monitor the snow loads and how it resist the winds.

Its replacement is going up besides in the Spring, after I finished levelling the spot, which has to wait until some plants in the way are moved ...

The spot in question.

I removed a bunch of saplings in the way and

removed root balls and roots everywhere.

I have a flat & level spot in the back, the front shows you

how much more I have to go up front.

It will end up a few inches lower than the other greenhouse besides it.

The one that takes a beating and keep on ticking

Still cleaning up and burning branches, weather permitting.

Got three burn days since, a few more to go...

So in between cleaning up, fixing up the greenhouse and recycling the old shed, which was supposed to get demolished this year, it get one more year... and I started a few woodworking projects of necessity.

My small basement shop got also turned upside down so to speak, with the installation of my old post inside for the post drill installation. All the parts are derusted, cleaned and painted as appropriate, just awaiting turning its wooden back board from a twisted potato chip into some semblance of straightness to be useable...

Meanwhile...

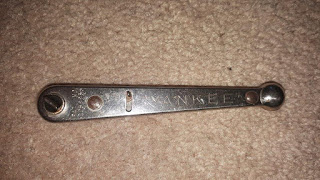

Got a few more tools thru my Evaporust in a piece of pipe set up, including screwdrivers, so decided to make some sort of stand or rack for them.

Looking at my pile of wood in the shop , came across a piece of maple molding, made on a shaper.

Thinking it would dress up my screwdriver holder. Note, I am strictly storing my Cabinet maker screwdrivers, AKA, have parallels edges, so making uses of the flat area in the typical British design.

Using a backer board, which I notched to received the flat part of the screwdrivers,

The basic idea I'm going for

Turns out my glue bottles are too old, 2005 and 2009.

Who knew? Apparently not me :-)

Only thing I could find a Wally Mart was Gorilla glue,

not foaming formula, more like a regular white glue??

Dries clear.

Of course the round shaft are thicker than the flat area,

so had to drill and or rasp a hole in the middle of each slot.

I like the spacing, that works for me.

And how am I supposed to secured it on a wall somewhere?

I decided to insert T-Bolt inside the sandwich, so I can use standard jig nuts and screws.

A tad overkill in hindsight :-)

Will go with a simple French cleat system for my next one.

I had a piece of that molding left over, so I tried a few things.

Marking gauges are next.

I could squezzed in 5 max, but which ones???

Then that leaves those other favorites out.

Plan B, use a flat, wide board, so I can layout two rows of gauges on it.

Found a suitable maple board, made a few templates first in scrap wood.

I used a No 16 Jennings bit (one Inch) spaced 2-1/2 in apart, in the back.

A tad tight depending on gauges selection and designs

Up front made customs holes for the gauges.

Spacing not to my liking.

The empty hole is made with a No 18 Irwin bit (1-1/8 inch)

Needed a bigger hole size than 1 inch to accommodate

the twin wooden beams gauges

Then made a new board with 2-1/2 in spacings between 1 inch holes and the next two holes 2-3/4 in apart next to it. Want to try various gauges combinations.

Decided to go with 2-3/4 in spacings between all the 1 in holes in the back row.

I use a special gauge to set my divider to a know quantity, in this case 2-1/2 in.

Easier than trying to use a ruler or tape measure.

Once I stepped out my distances, I used an automatic punch to

register the locations for the drill bit following

Making it easy to drop the Forstner bit into it.

Took some fiddling with the holes, turns out the Jennings I was using is a smidgen bigger than 1 inch, Some of the gauges are a tighter fit. Made one bigger hole to accommodate the twin beams gauges.

The holes up front for the metal gauge I duplicated the forms I used previously on my scrap board, except I had the bright idea of using the powered jig saw to cut a square hole and made a mess, went in La La land and oups, shit!

NO biggie, will cover up the hole with some banding later, for now look marvelous with the gauge covering its hole :-)

That work and I left room for a future Tite Mark gauge, because... :-)

Hold ten gauges of various shapes and forms, room for 11.

Should be enough to see me through at least two simultaneous projects.

Now will need to figured out some sort of holder for the gauge board. And where are those holder going anyway??? Oh, I have some idea, but that includes some more re-arranging :-)

In other news, our car is back from garage, last exactly about 100 Kms before engine light came on, was the camshaft sensor, which they did not replaced so not warranted Grrr..

Not trusting much the car, bought a truck. Will be more reliable and will help me a great deal with some projects around the yard for sure. Not to mention to move wood :-)

My new to me 2011 GMC Sierra.

One owner, well maintained.

It never ends does it? :-)

Bob, with a full plate, puttering in between